22 June, 2020

Walking along the shores of the Red Sea, Adnan Qamar, WDRC System Modeling Specialist, and Ahad Syed, Corelabs Lead, Safety & Facility often discussed the novel

COVID-19 pandemic which had turned the world upside down. Recalling the grim pictures that were circulating the news, the duo often wondered how developed countries even struggled to provide specialized medical care for the infected. The discussions

progressed into the desire to do something in the fight against the COVID-19. Their opportunity came when KAUST Innovation and Economic Development (I&ED) announced

the

COVID-19 Innovation Challenge, calling on the KAUST community to come with ideas, approaches, and products to stay safe and healthy.

Immediately, Adnan got in touch with his elder brother, Dr.Sameer Qamar, MD, an internal medicine physician at the Miami Valley Hospital, in the United States. Adnan wanted to get first-hand information on the issues severely impacting the medical

care from Dr. Qamar, who is a frontline worker. Adnan learned the hospitals were fighting against time, space, and money at the same time. There were not enough beds and ventilators for everyone.

As the team deliberated on these issues, they concluded that non-portable ventilators, which require a plumbed oxygen supply in the hospital, is an obstacle to providing respiratory treatment to COVID-19 patients. Combining Adnan's experience in system design, biomedical and mechanical devices, and Ahad's gas system knowledge, the idea of "Ventibag" was born. Ventibag is a portable ventilator that would supply oxygen directly extracted from the air, making it possible for patients to receive specialized care in the comfort of their homes. More importantly, with novel Artificial Intelligence (AI) technology embedded in Ventibag, the medical practitioner could control the Ventibag remotely, making frequent home visits unnecessary, thereby limiting the spread of the disease and reducing the number of infected patients.

Ventibag is a portable ventilator that would supply oxygen directly extracted from the air, with novel Artificial Intelligence (AI) technology enabling remote monitoring of use with patients who are infected.

Working through Zoom, they stitched together the idea and submitted a proposal for the COVID-19 challenge. A few weeks later, they received the good news that Ventibag was one of the six projects selected

from over a hundred applications to go to the next round. The final pitch delivered by Adnan met an overwhelming response, receiving a $20,000 fund to produce a prototype. "We are profoundly grateful to KAUST I&ED for encouraging our idea and

acknowledging that Ventibag could help the medical care", Adnan said. They are also highly appreciative of KAUST President, Dr. Tony Chan, for his words of encouragement and recognizing how this home-built portable ventilator can also contribute to

KAUST's commitment to Saudi Arabia's Vision 2030.

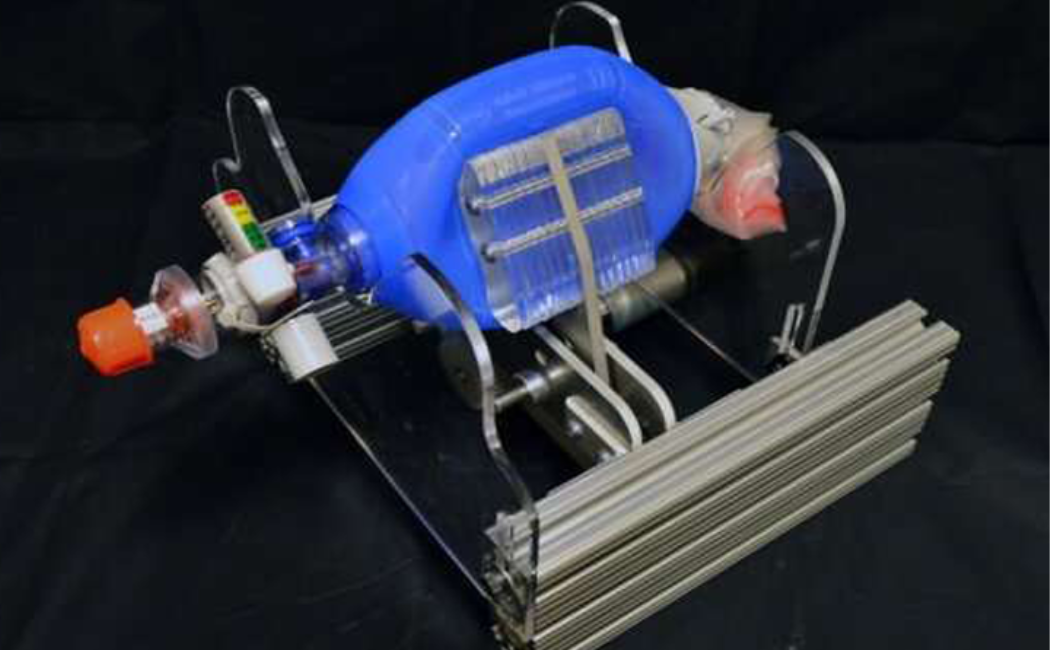

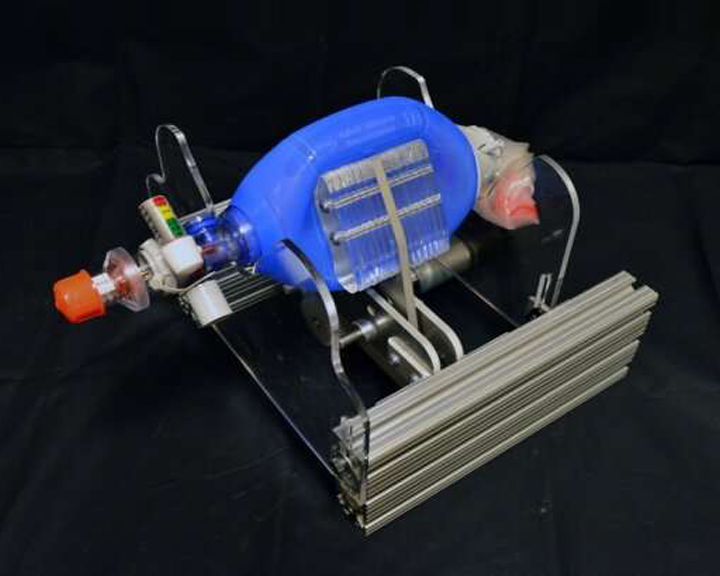

The team is confident that Ventibag will capture the market. In commercial ventilators, pure oxygen is supplied through wall ports or oxygen cylinders; thus, immobilizing patients. Meanwhile, the Ventibag comprises only two sections; (a) the electro-mechanical

system equipped with the paddled flexible diaphragm (b) the gas-metering assembly through miniaturized pressure swing absorption technology (produces pure oxygen on-site, extracted directly from the air). As there is no dependency on separate bulky

oxygen supply, the whole system can be encased in a bag-sized pack and used unrestricted at any location.

With the threat of COVID-19 still looming and the suspension of international flights and cargo services, the Ventibag project is easier said than done. One of the significant challenges would be the procurement of items for fabricating the prototype.

Some of the components are available only internationally, and it is an uphill challenge to get them to KAUST. Miniaturization of the Ventibag to be easily portable is another anticipated roadblock. Finally, as proof of a working prototype, the Ventibag

must be tested by a certified physician. With the enormous pressure and workload doctors are under nowadays, the team is worried this step would encounter some delay.

KAUST colleagues and friends, Adnan Qamar and Ahad Syed are now the teams behind the Ventibag.

But, the team will not let these potential roadblocks deter them. The plan is to have the design completed within three months before proceeding to component procurement. Once the components arrive on-site, fabrication will commence with hopes of a prototype ready within six months. The next steps would be optimization, cost-effectiveness, and moving to large-scale in-house production based on how the prototype performs and the potential impact on the market.

The effects of COVID-19 are long-lasting. Lives all around the world have been turned upside down. From having exotic items delivered to your doorstep, the struggle is now to get essential things like bread and water. Stories about depression, job cuts, and loss of loved ones and a general sense of despair in many parts of the world are daily news. In these unprecedented and challenging times, the story of these two scientists is an inspiration on how to turn a crisis into a noble opportunity, which could potentially save thousands of lives.