A fast and safe method to prepare a 3D porous material that mimics the shape of a honeycomb could have broad applications from catalysis to drug delivery or for filtering air to remove pollutants or viruses.

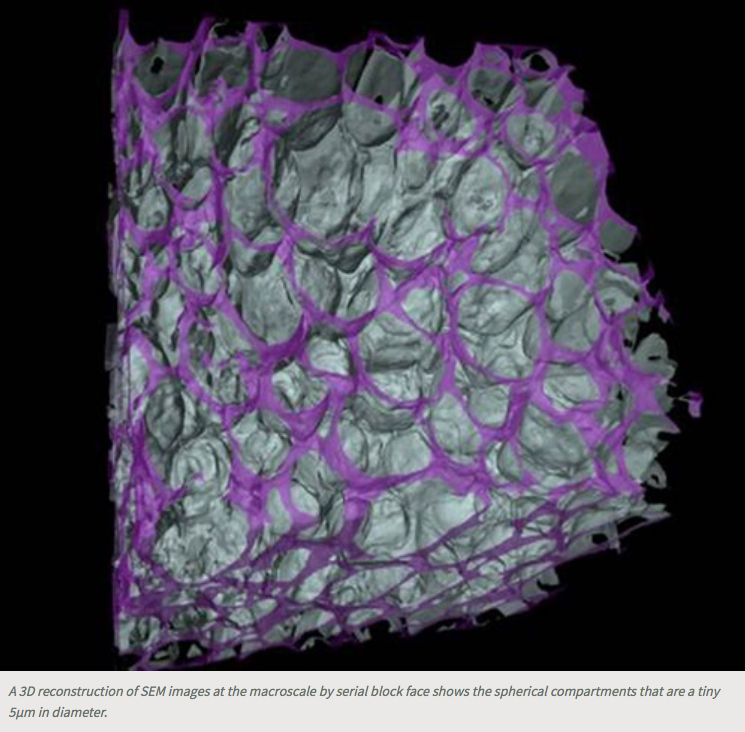

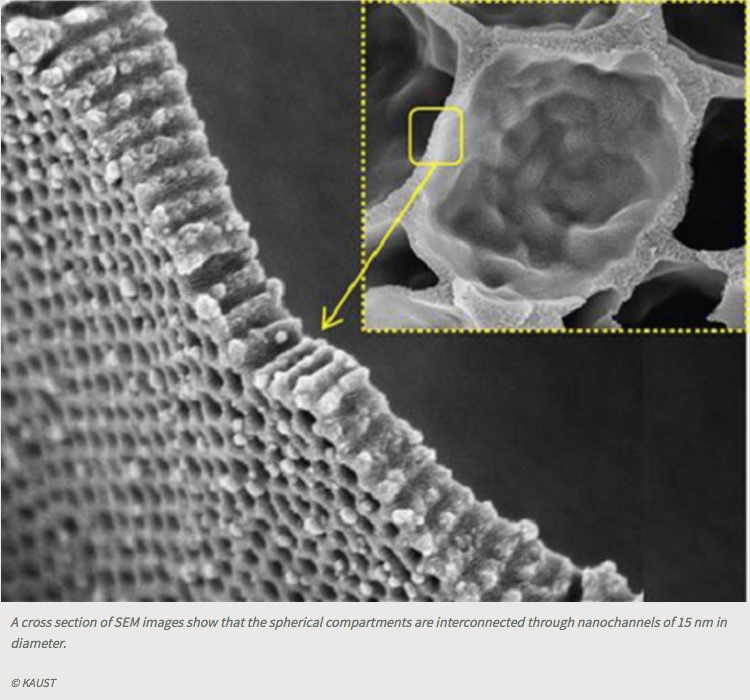

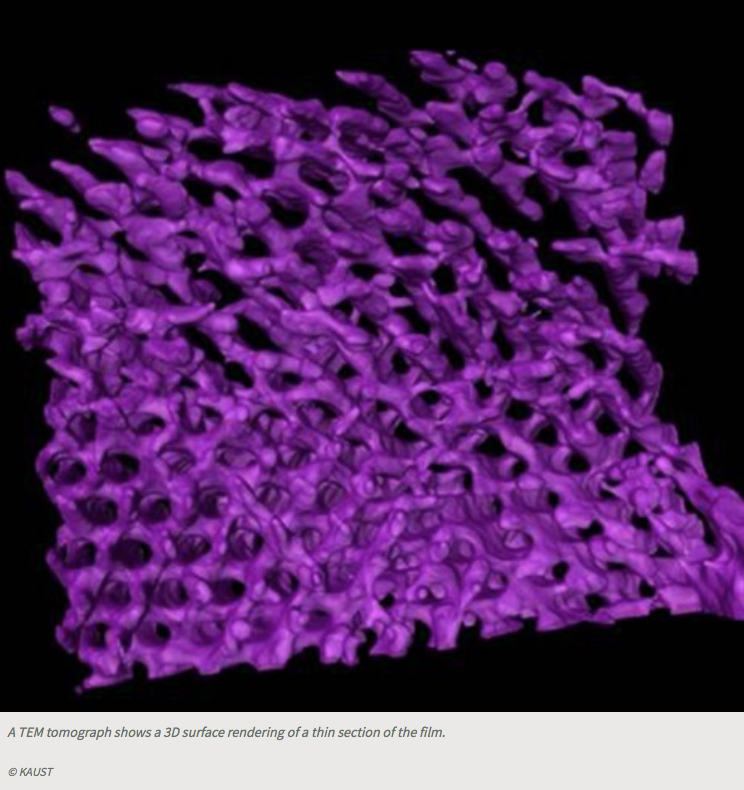

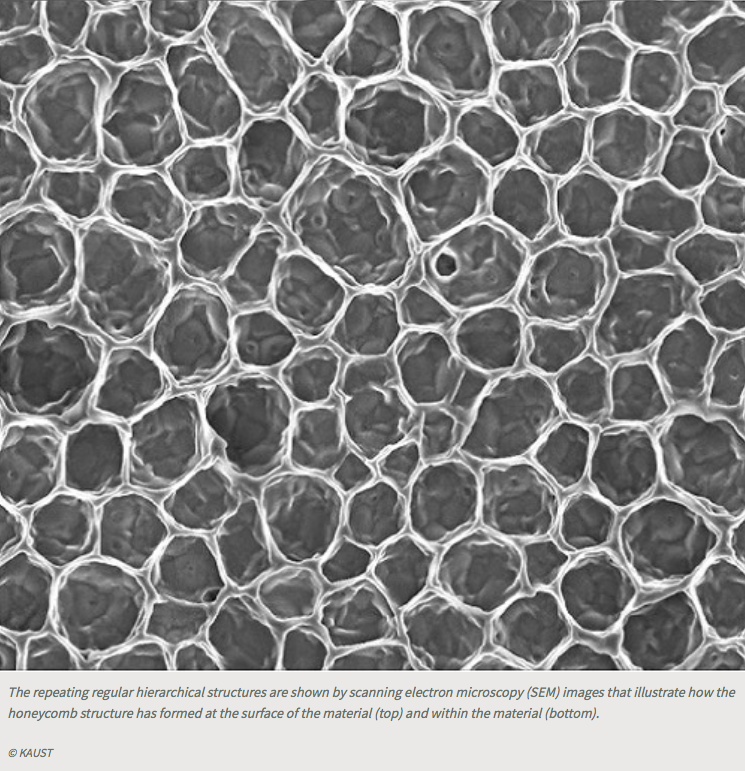

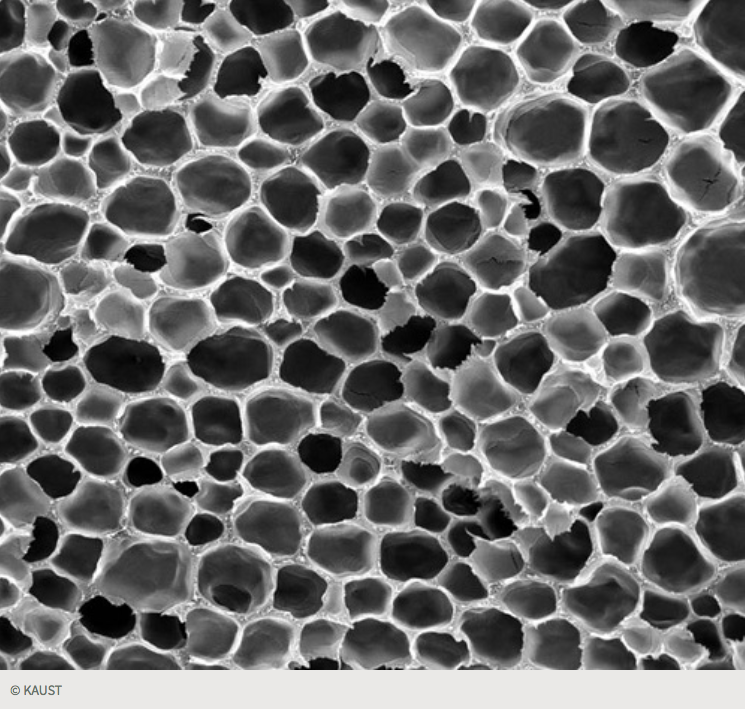

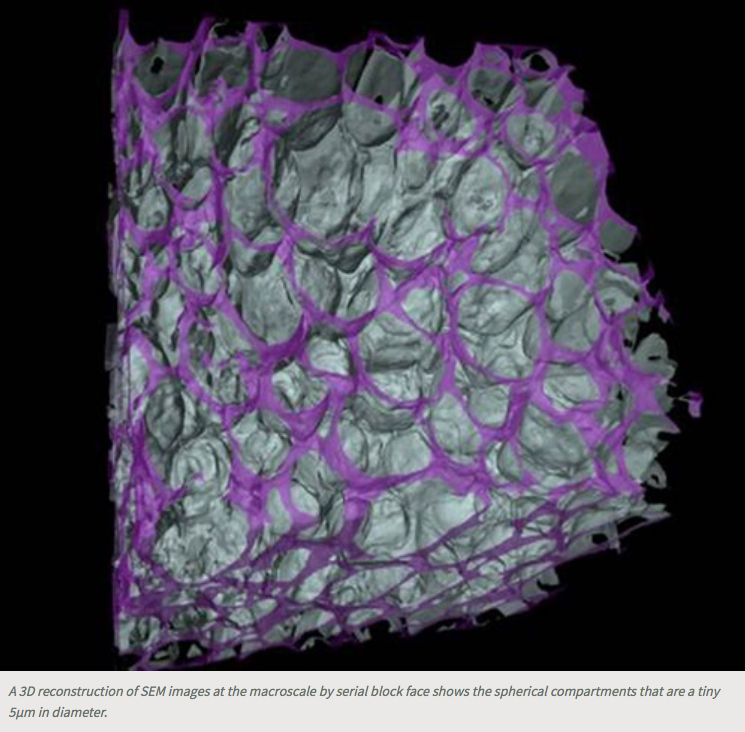

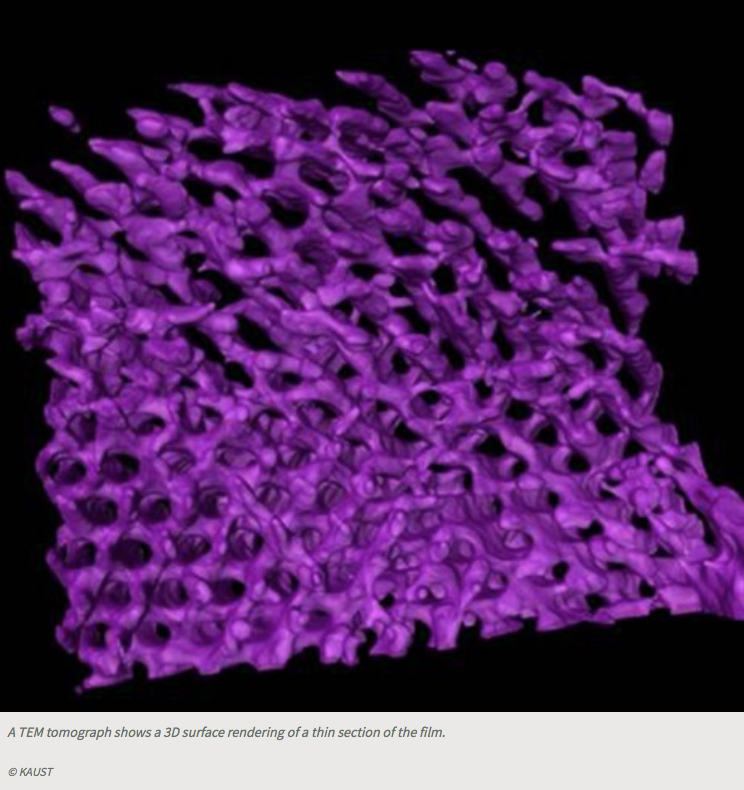

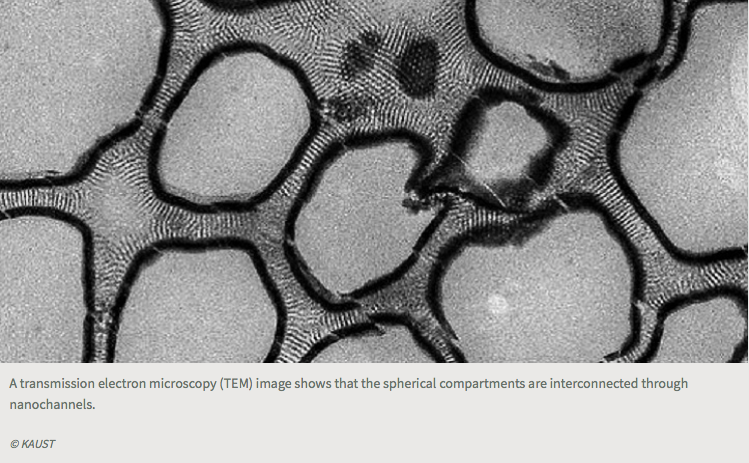

The lattice of a honeycomb or the symmetry of a diatom are among complex living structures whose patterns and shapes have long inspired scientists. One recent application is to develop artificial hierarchical porous materials that are stable, yet have

a large surface area and the ability to selectively extract materials. The complexity and pattern repeatability across scales from individual compartments to the entire structure, have made it difficult to build them at the nanoscale.

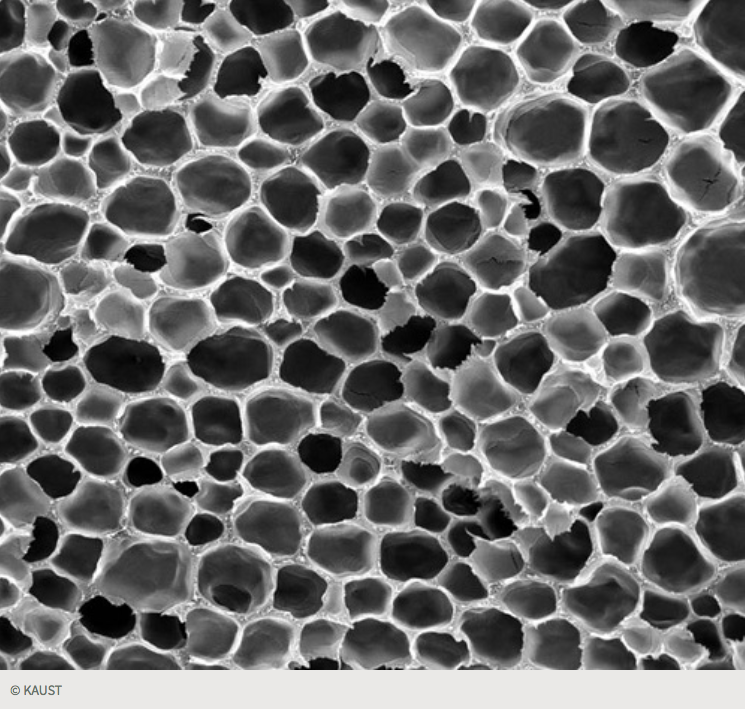

A team from KAUST, led by Suzana Nunes, has proposed a simple method that, in just five minutes, can produce a flexible film with a complex hierarchical structure that has repeating patterns of interconnected, regularly shaped pores.

With experts in the Imaging and Characterization Core Lab, the researchers used the block copolymer called polystyrene–b–poly (tertbutyl acrylate) (PS–b–PtBA) to demonstrate this method. They tested various concentrations

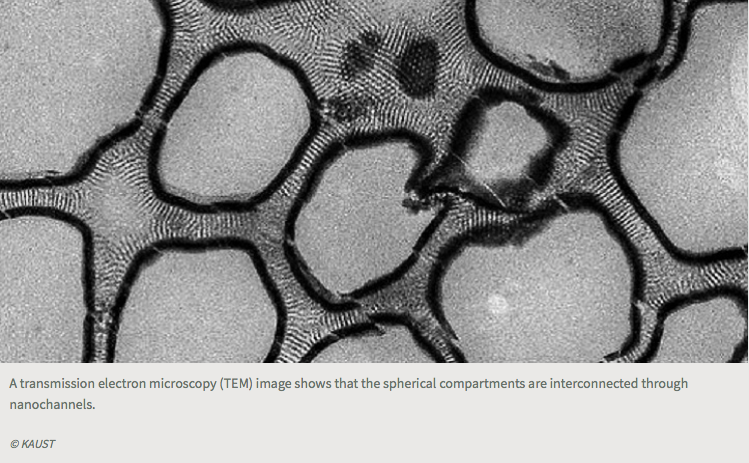

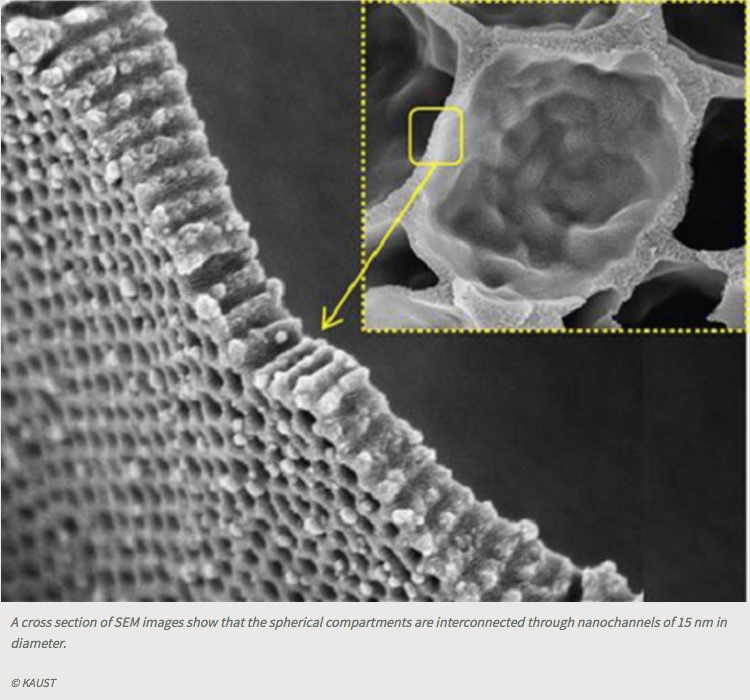

of PS–b–PtBA with different solvent mixtures with the resulting solution cast on a glass plate and evaporated for different time periods to promote the nucleation and growth of cavities with highly porous interconnecting walls. The resulting

film was then immersed in water to rinse off the solvent and halt the phase separation.

“By using this method we create an important platform to design artificial porous materials which replicate a highly ordered porous and complex systems mimicking nature,” explains lead author, Stefan Chisca. “These have potential use

for separations and biological scaffolds.”