19 March, 2018

-By Lulwah Shalhoub, KAUST News

As Saudi Arabia moves towards reliance on sustainable sources of energy, KAUST is developing and commercializing new cycles for seawater desalination using solar energy.

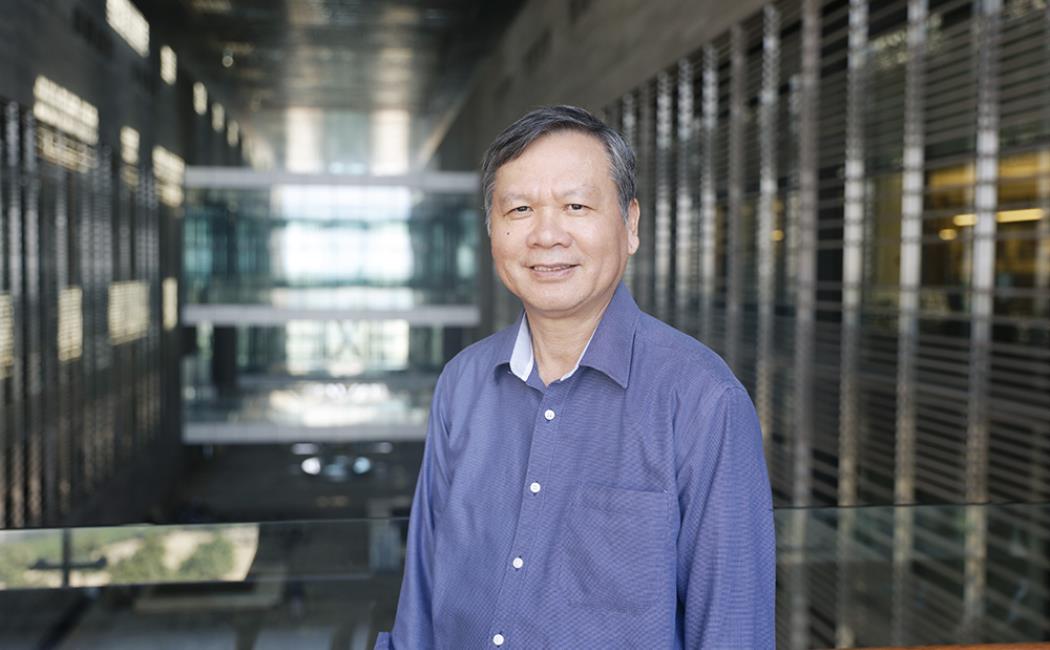

"Low energy desalination is in line with Saudi vision 2030," said Kim Choon Ng, professor of environmental science and engineering at the Water Desalination and Reuse Center (WDRC) under the Biological and Environmental Science and Engineering Division (BESE).

"Our research in the lab translates to industry. It is not only innovative, but it is also low in energy consumption and maintenance costs," he added.

Ng developed a process that combines adsorption desalination (AD) and multi-effect distillation (MED) to boost thermodynamic synergy between the two cycles. The combined cycle, known as the MEDAD cycle, yields significantly higher water production performance when compared to conventional MED desalination cycles.

"I hybridized the AD cycle with MED to boost the production of water, which was the idea behind setting up the spinoff company MEDAD in 2012," he said.

Ng pioneered a similar cycle in 2010 at the National University of Singapore (NUS) for space cooling.

"When a team from KAUST visited NUS, I showed them the facilities and a member of the visiting team asked: 'Why don't you use it for desalination?' That's how I started using the cycle for seawater desalination," said Ng, who co-founded the company with his son Joseph Ng, who is currently the CEO.

The innovative AD cycle desalinates seawater using solar energy that is utilized to regenerate silica gel adsorbent. Solar energy at a temperature of 60 to 80 degrees Celsius is sufficient for regeneration, and the renewable solar energy is available in abundance in Saudi Arabia. The desorbed vapor from silica gel, after supplying regenerated heat from solar, is than condensed in the seawater-cooled condenser. Once the vapor is condensed, it becomes pure water.

"This water becomes drinkable after some post-treatment as it lacks minerals, and calcium is added for mineralization of the water whilst ozone gas is added to disinfect the water for potable purposes," Ng explained.

The hybridization of AD with MED boosts water production almost twofold at the same temperature.

"Doubling the water production at the same heat input temperature reduces the water production cost," said Dr. Muhammad Wakil Shahzad, a research scientist at WDRC. MEDAD cycle water production cost is the lowest at $0.48/m3 compared to multi-stage flash distillation, which costs $1.201/m3.

MEDAD collaborated with King Abdulaziz City for Science and Technology (KACST) in its desalination projects. The first 100 m3/day commercial scale project was commissioned in February 2017 at Solar Village, KACST, Riyadh, and it is working successfully with solar and an auxiliary boiler. At the same time, another MoU was signed with KACST for 2,000 m3/day to be installed at Yanbu at the Saline Water Conversion Corporation (SWCC) site.

The project was inaugurated in February 2017 by the Minister of Energy, Industry and Mineral Resources and KAUST Board of Trustees Vice-Chairman Khalid Al-Falih and KACST President Dr. Turki bin Saud bin Mohammed Al-Saud in the presence of KAUST Interim President Nadhmi Al-Nasr.

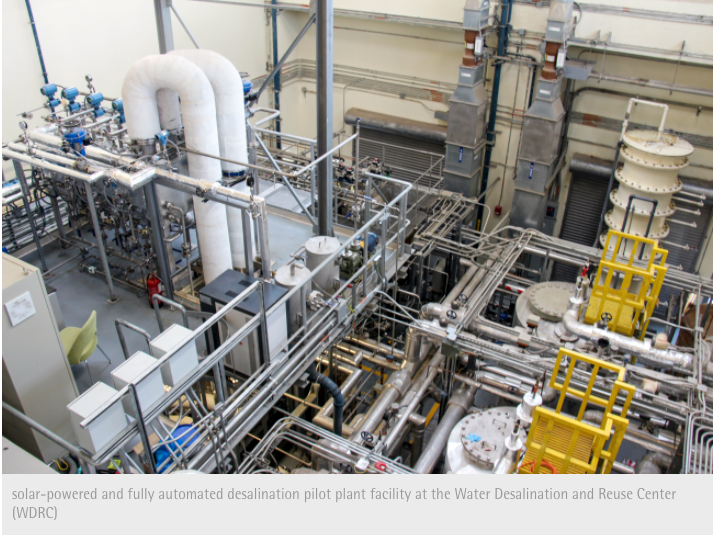

MEDAD's desalination technology won the Aramco-GE Global Innovation Challenge award for seawater desalination in 2015. The award went to the lowest cost per cubic meter of water production. The KAUST-based WDRC has a solar-powered and fully automated desalination pilot plant facility that generates 8 to 10 m3 of desalinated water per day. The facility occupies a laboratory space of 200 m2.