Immersion could become the ultimate test for assessing the wetting properties of coating-free microtextured surfaces.

The textbook directions for characterizing the wetting properties of solid surfaces are likely to change as KAUST researchers demonstrate that conventional tests can be misleading¹.

Current go-to methods to determine surface wetting characteristics rely on measuring contact angles, whereby images of advancing and retracting droplets dispensed by capillaries onto surfaces are analyzed to estimate angles at solid-liquid-vapor interfaces.

A contact angle exceeding 90 degrees for water- or oil-based droplets indicates surfaces are hydrophobic (water repelling) or oleophobic (resistant to oil). Therefore, surfaces that meet this criterion for both water and oils are defined as omniphobic. High contact angles also ensure that, when immersed in liquids, surfaces entrap air, which is crucial for applications, such as desalination, drag reduction in transport pipes and antifouling materials for ships.

Contact angles have proven extremely reliable for assessing the omniphobicity of surfaces that exploit liquid-repellent chemical coatings. Commercially available equipment and software exist for measuring real-time contact angles. However, in exploring coating-free approaches to repel liquids, Himanshu Mishra’s team found that assessments based only on contact angles can be deceptive.

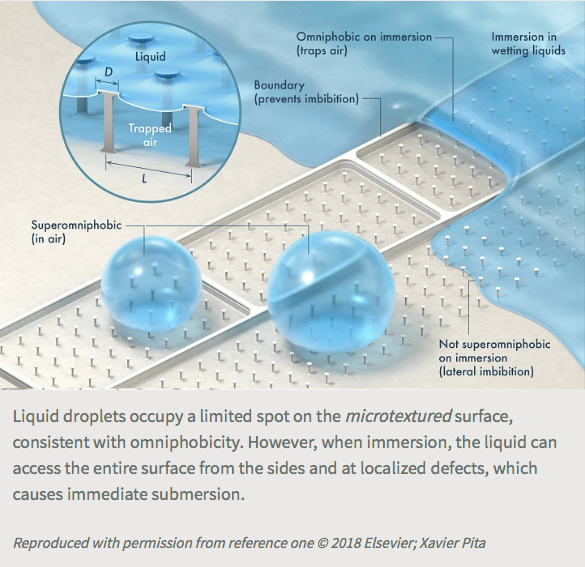

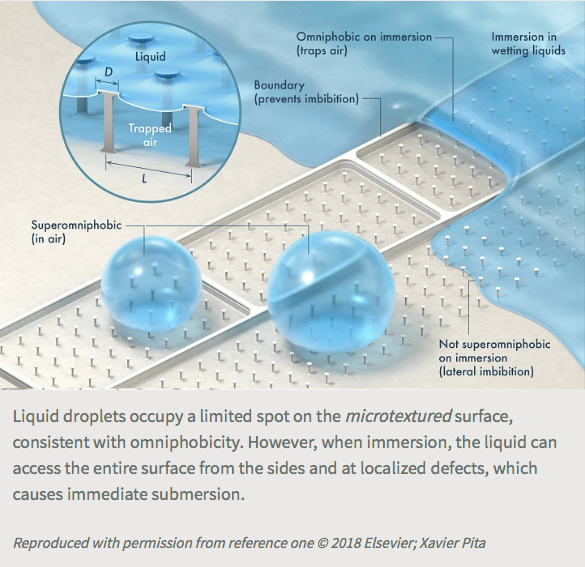

To demonstrate this discrepancy, the researchers investigated the wetting of silica surfaces comprising microscopic mushroom-shaped pillars (see image) by both contact-angle measurements and by immersion. When assessed by contact angle, the surfaces exhibited advancing and receding angles greater than 150 degrees, which according to the index used to evaluate surfaces classifies them as having remarkable liquid repellence or superomniphobicity. However, when assessed by immersion, the same liquids instantaneously imbibed the microtexture and the phobicity was lost. Thus, surfaces that were characterized as superhydrophobic through contact angles led to flawed conclusions. In reality, localized defects, such as broken or missing pillars, in this microtexture and boundary enabled the liquid to penetrate and displace the trapped air.

Using the same material, the researchers also demonstrated that if a wall was built around the pillar arrays, the resulting compartmentalized microtexture repelled liquid droplets in air and trapped air robustly on immersion (see image). “As we identify new coating-free approaches to liquid repellence, the old criteria for assessing omniphobicity need to be updated, and the specificity of microtextures has to be recognized”, said Mishra.

First author Sankara Arunachalam, explains that “during contact-angle measurements, the droplets occupy a limited number of spots on the surface. Therefore, effects of surface defects might be missed.” However, the liquid can access the entire surface upon immersion. These findings are expected to advance the rational development of coating-free liquid-repellent surfaces as green and robust alternatives to current chemical treatments for applications, such as desalination and drag reduction.